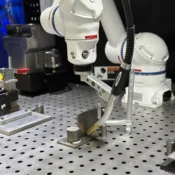

Tri-State Automation introduces its easy-to-use collaborative welding robot (Cobot) welding cell that delivers the industrial throughput and quality you expect from TSA. The new Yaskawa HC10 and HC20 welding cobots empower your welders with the flexibility and skill to create new robotic welding jobs on the fly – then quickly redeploy them for the next welding challenge. If you perform highly varied fabrication runs or find your welders scrambling from job-to-job during the course of a day, welding with a cobot can provide you with better, affordable options that will yield quick results. TSA builds cobot welding cells to adapt to your working environment – not the other way around. The durable, simple-to-operate design works with a variety of torches, fixtures, carts, and welding power supplies.

Highlights

- Faster Turn Around: Easy set-up and teaching enable you to say yes to more jobs, deliver them on time and be more profitable.

- Steady Staffing: Short-handed? No problem. Welders can teach the cobot repetitive jobs, then move on to more skilled welding tasks.

- Consistent Results: Let your cobot handle long seams and heavy deposition to maintain quality where physically demanding work often falls short.

- Hand-Guided Teaching: Welders teach the robot by guiding it to the weld points. Torch angles and arc on/off can all be set from the teaching collar.

- IP67 for Extra Protection: Designed to work in fabrication shops and other rough environments, the IP67 exterior of the HC-series robots are easy to clean and built to last.

- Safe for Welders: Power and Force Limiting (PFL) technology monitors force and reacts quickly to contact, enabling safe collaboration in a fenceless environment.